Corrosion Protection For Steel Substrates

The Fight Against Corrosion

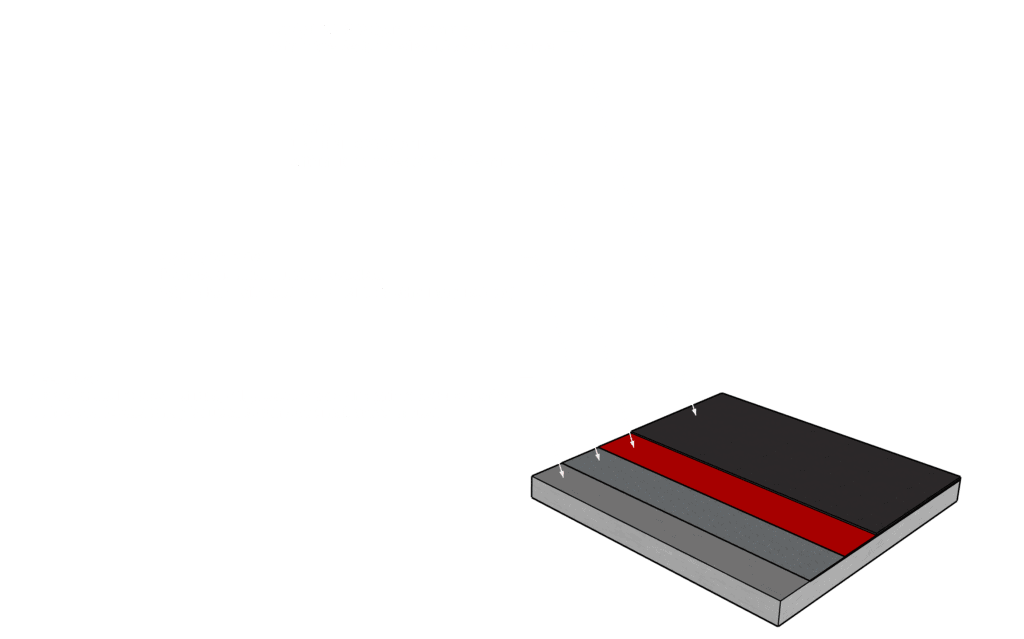

In construction, steel structures require adequate protection against corrosion. A corrosive-barrier needs to be durable, moisture and chemical resistant and maintenance-free to provide long-lasting protection.

PAXCON polyurea coatings provides extreme durability, scratch-resistance, chemical-resistance, waterproofing and corrosive protection.

Traditional coatings, such as epoxy, are not as durable as PAXCON polyurea.

Polyurea Coatings by PAXCON are environmentally safe, containing no VOC’s and comes with various colours options.

For manufacturers, there are numerous reasons why to choose PAXCON for adequate protection against corrosion,

Environmentally Safe

Enhanced Durability

Quick Return To Service

Various Colour Options

Chemical Resistance

Waterproof

Developed by a team of leading in-house chemists

PAXCON Polyurea Systems create an impenetrable barrier between valuable steel assets and harsh environmental surroundings such as high humidity, saltwater and extreme temperature changes.

A diverse range of advantages

The application of PAXCON Polyurea Systems has a diverse range of advantages compared to other coating systems. PAXCON is well renowned for its extreme durability and scratch-resistance, resulting in less maintenance and downtime.

With no volatile organic compounds, PAXCON Polyurea Systems provide an environmental competitive edge compared to traditional polyurethane systems.

Proven corrosion resistance - Worry-free maintenance

PAXCON Polyurea Systems are proven to provide exceptional protection against corrosion. With ASTM B117-Salt Spray testing, (a well renowned corrosion test designed to provide corrosion resistance information on metals and coated metals), After 3000 hrs exposure, PAXCON Polyurea Systems (with the correct blasting and priming) was rated 10 with no failure on the coated panels.