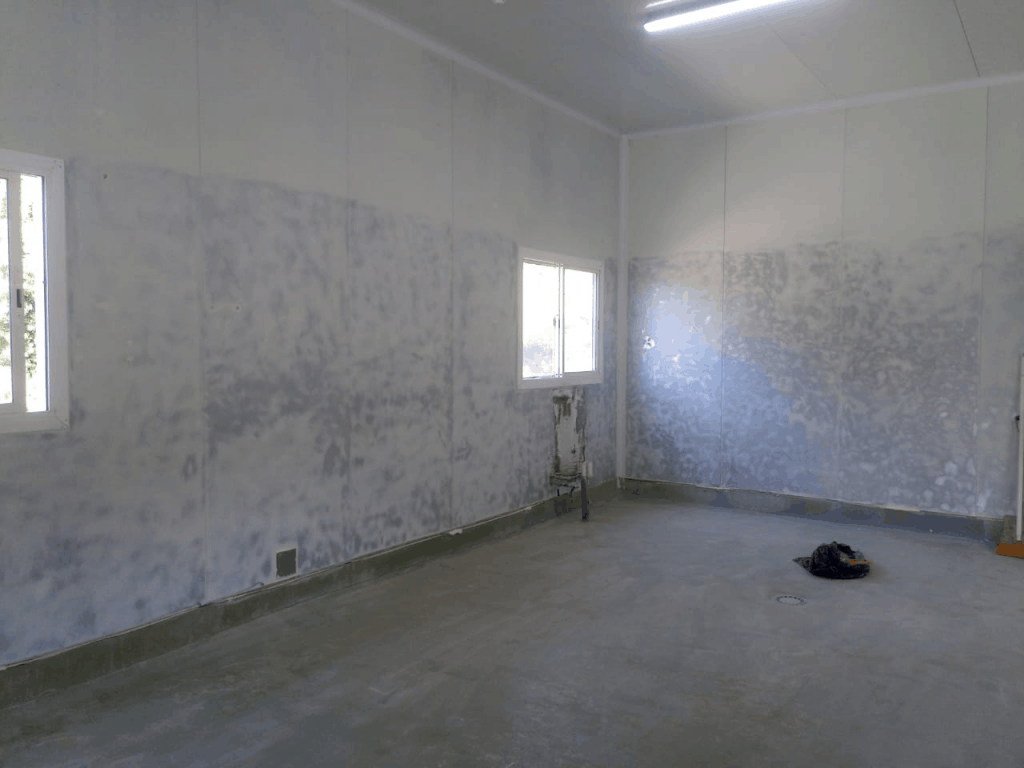

Corrosion is a plague to modern manufacturing; it can strike any industry in any part of the world – even a traditional cheese shop in Cyprus. The walls of this cheese production facility were constructed from steel sandwich panels. Every day, these panels are exposed to salty steam and liquid spills. Most cheese production uses acid and salt at specific stages to make cheese. After so many batches, the steel panels would begin to corrode. The panels often sustained further damage by the collision with and impact damage caused by stainless steel trolleys used to harvest the cheese or progress to the next stage in the process.

The manufacturer had two options: replace the panels with new ones and face the same issues in the future, or find a protective coating that could withstand the environment for longer service life. Whatever the solution, the manufacturer could not stop production for longer than four working days.

Fast Solution With Extreme Resistance To Corrosion

Needing a solution that could be achieved quickly and with extreme resistance to corrosion, the company chose a polyurea coating and the expert applicators at PAXCON.

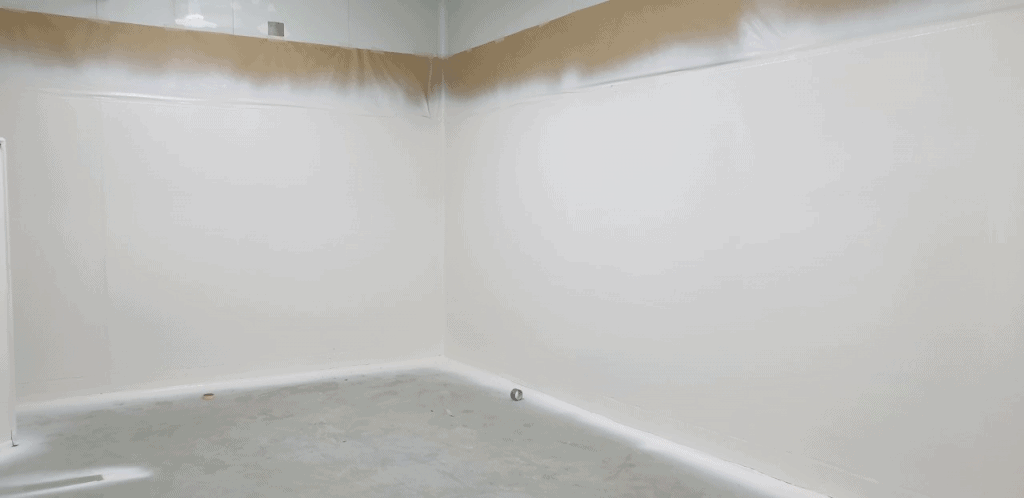

PAXCON applicators worked quickly to make sure the area was prepped, primed, and the coating cured within the company’s four-day timeline. Spray technicians removed rust and debris from the panels, grinding certain areas as needed, then cleaned and applied a rust converter to avoid the potential for rust to spread on the substrate. The team then added a specialized primer to the metal, one that would help the PAXCON coating adhere to the surface. Once complete, a pure polyurea called PAXCON XS-350 was sprayed onto the cleaned and primed surface.

PAXCON, Perfectly Suited For Food Service Application

The finished product exceeded the expectations of the manufacturer. Not only was the application completed within the timeline for a fast return to service, but the coating was sprayed in white for a clean appearance. As production resumed, the client was very happy with the immediate results. The panels could take the impact of the trolleys with no damage or abrasion.

Additionally, PAXCON is perfectly suited for a food service application because the coating contains no VOCs and is rated for incidental food contact by various governments including the FDA and USDA in the United States.